Al Gore often ends his presentations on climate change by showing a classic image of the Blue Marble – the full sunlit disk of the Earth, hanging vulnerably against the blackness of space – before adding some cautionary words: ‘Don’t let anyone tell you we can escape to Mars; we couldn’t even evacuate New Orleans. The Earth is the only planet habitable for human beings. We’re going to have to make our stand right here.’

This is a rational view of the challenge. We have to deal with famine and disease. An estimated one billion people live on less than $1.90 per day. Climate change is threatening a tenuous global economy. Why would we invest resources on colonising another planet when we need them so urgently on Earth? Such thinking extends up to the highest levels of government. Although it has announced plans to send astronauts to Mars orbit sometime in the 2030s, the Obama administration has with each annual budget request attempted to direct NASA funds away from human spaceflight and planetary science, and toward Earth observation.

But lately I’ve found myself wondering: what if our societal view of problem-solving is flat-out wrong? More specifically, what if addressing a crisis directly is not always the most effective route to success, and investing resources toward a different, seemingly unrelated challenge could lead to faster, more effective breakthroughs?

It sounds like a wild claim, but this indirect approach, known as lateral innovation, is responsible for many of the most remarkable innovations we encounter in our daily lives, generally with little awareness of where they came from. One of the most dramatic recent examples is the graphics processing unit (GPU). Fast, powerful GPUs were originally developed to meet the demand for increasingly realistic video games, especially ultraviolent first-person shooters. But machine learning, computer vision and neural networks pose very similar computational challenges, and the technology quickly migrated over. Specialised GPUs are now used for diagnostic medicine, facial recognition, self-driving cars and market forecasting. Built on innovations developed for games such as Doom and Grand Theft Auto, machine learning is powering one of the fastest-growing sectors in the world economy.

About a year ago, I joined a company called Planet Labs in San Francisco, and stumbled into a veritable nest of lateral innovation. As an ecologist, I’ve spent much of my career researching challenges such as deforestation, rising carbon emissions and the loss of biological diversity. In my search for solutions, I’ve walked the halls of academia and the US government, but at Planet Labs my work has taken me to a place I never expected to be: low Earth orbit. Through the eyes of dozens of microsatellites, each the size of toasters, I watch the world’s forests change every day. I collaborate closely with the people who build the satellites, write the control software, and convince skeptical agricultural firms to pay millions for the pixels of data they collect. All of this happens on budgets that are minuscule by NASA standards, using hardware and code that were mostly developed for other purposes.

Watching what my colleagues do, and understanding why they do it, has convinced me that brute force alone will not innovate the technologies that will enable human civilisation to become an effective arbiter of this planet and her resources. The solution requires tapping into the same impractical, impatient, passionate drive that spurred the video-game-fuelled GPU revolution. And although that kind of lateral innovation cannot be instituted forcibly, it can be recognised and fostered.

In short, Gore got it exactly wrong. To save the Earth, we have to go to Mars.

The challenges of surviving on Mars are extreme, but they are hardly alien. Among the most basic steps for colonising Mars are growing food in a cold, arid environment and generating energy without fossil fuels. Today, international development organisations are experimenting with crops that achieve the same basic goal: to produce calories in inhospitable environments. Salt-tolerant potatoes in Pakistan. Drought-tolerant maize in East Africa. Nutrient-rich rice in India. The difference is that the Martian problem requires much more extreme, innovative solutions.

The great agricultural revolution of the previous century was fuelled by lateral innovation. Working in Mexico with the support of the Rockefeller Foundation in the 1940s to 1960s, the biologist Norman Borlaug kicked off a series of world-changing innovations in farming. Among the most important was ‘shuttle breeding’, a technique Borlaug used to conduct two full growing seasons in the same calendar year. Not everyone was pleased with his unconventional approach. As Mark Stuertz wrote in the Dallas Observer in 2012, Borlaug’s ‘rapid progress drew scowls from fellow wheat breeders and geneticists who maintained wheat strains could only be bred within one specific environment’. Opposition from his boss even led Borlaug to resign from the Rockefeller-backed project.

The labs that simulate the surface of Mars are trafficked by astrobiologists and physicists playing Kerbal Space Program on the side. Different minds see different solutions

When a colleague intervened and Borlaug was reinstated, not only did he make good on the plan but, by virtue of the differences in climate and soil at his two test sites in Mexico, Borlaug stumbled into one of his most important innovations. ‘As it worked out, in the north, we were planting when the days were getting shorter, at low elevation and high temperature,’ he explained. ‘Then we’d take the seed from the best plants south and plant it at high elevation, when days were getting longer and there was lots of rain. Soon we had varieties that fit the whole range of conditions. That wasn’t supposed to happen by the books.’ Problem-solving to breed plants more quickly in Mexico led to better breeds, and to more food. What insights might emerge from engineering potatoes to grow in the cold, arid, dim environment of Mars?

The challenge of engineering Martian crops also attracts a different group of thinkers and occupies a different institutional community than those who traditionally work in agricultural research. Developing salt-tolerant potatoes in Pakistan involves international development programmes, local farmers and land-owners, and private-sector agricultural companies. The laboratory environment used to simulate the surface of Mars is trafficked by astrobiologists and physicists drafting manuscripts for peer review and playing Kerbal Space Program on the side. Different minds see different solutions.

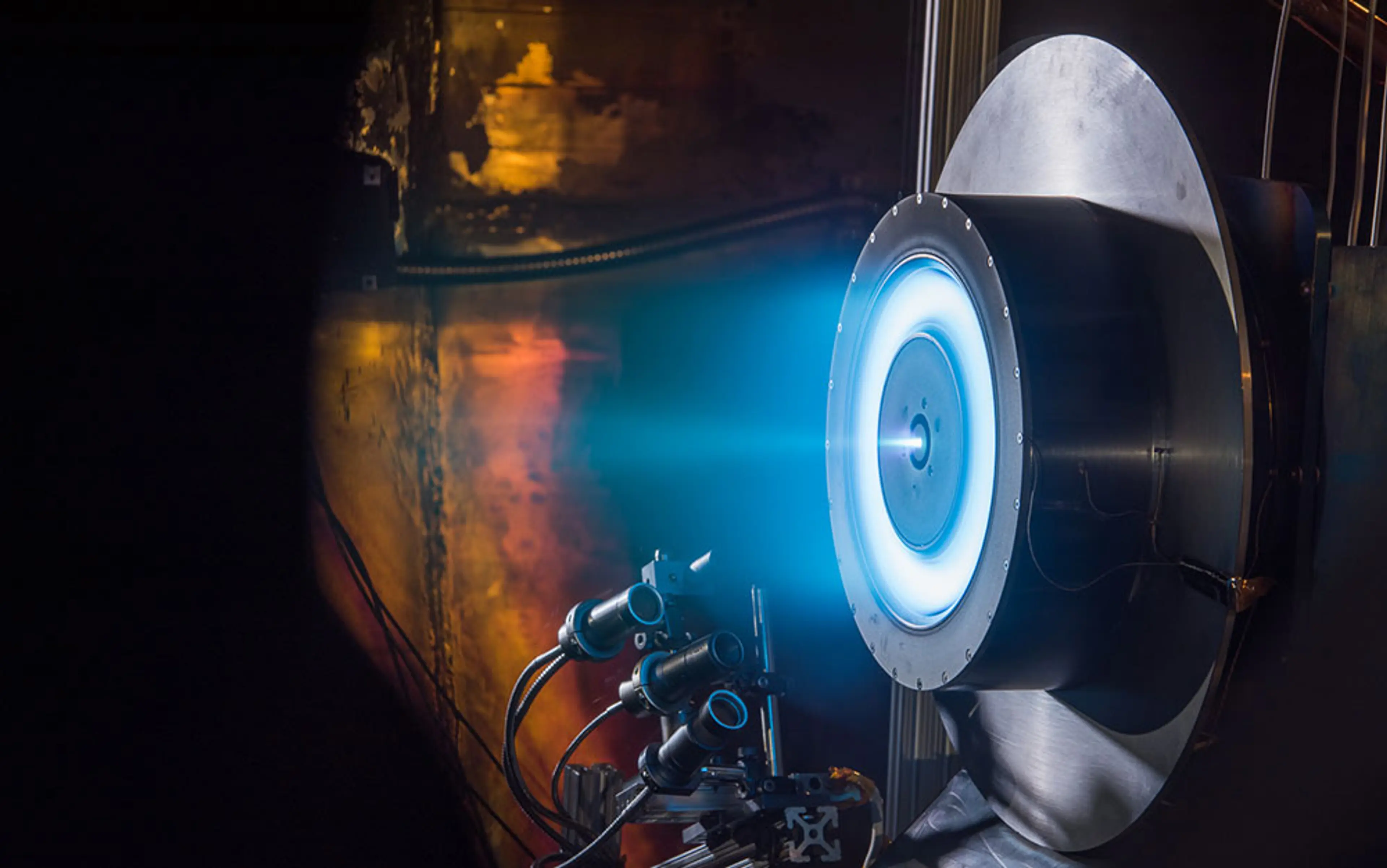

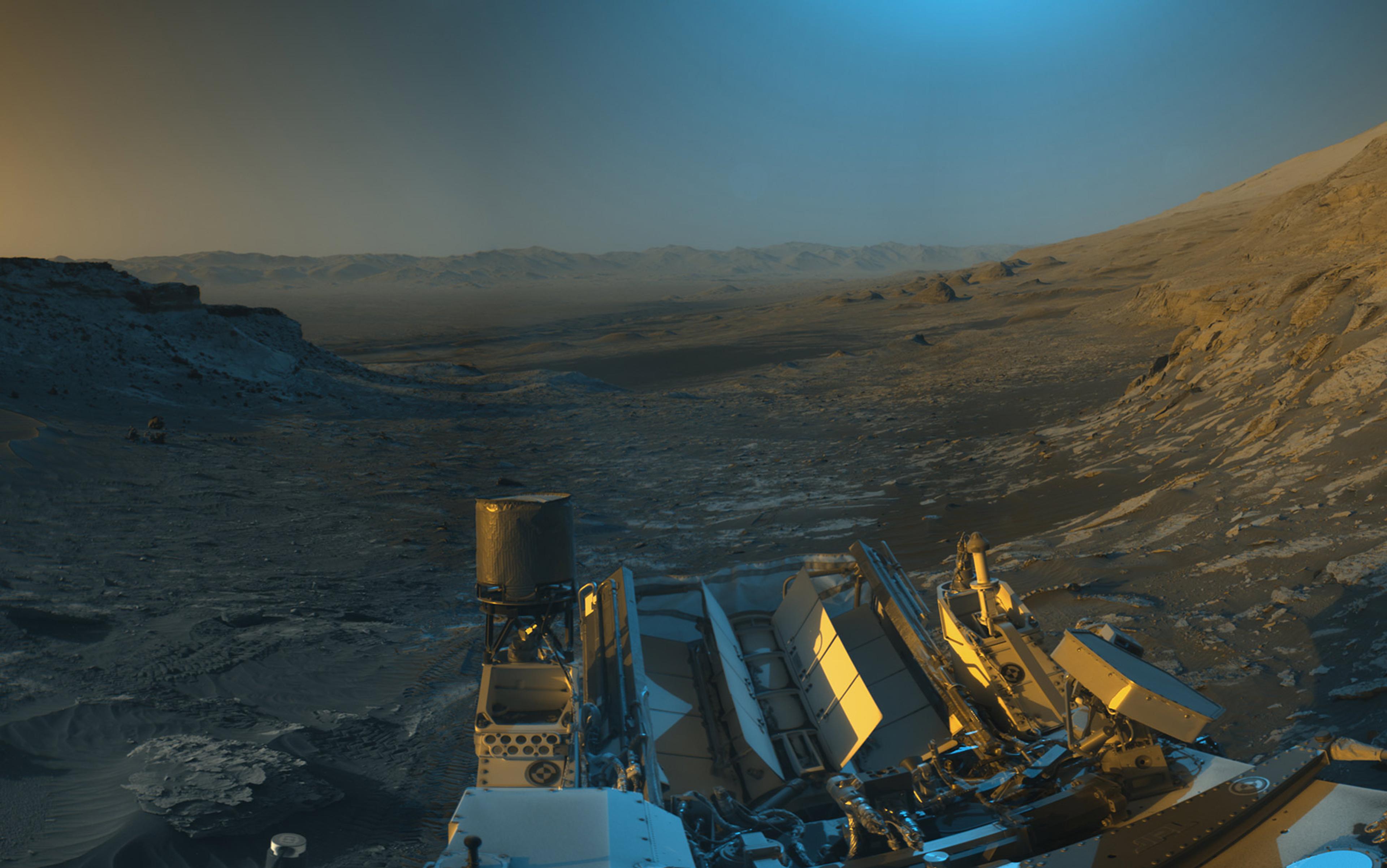

In energy production, too, technology development for a Mars colony could be game-changing for Earth’s needs. Solar and nuclear power are the only energy sources that have ever powered craft on Mars: the robotic probes that include the still-active Opportunity and Curiosity rovers. Mars lacks any fossil-fuel deposits, has no flowing water for hydropower, and its wispy atmosphere cannot push fins around a rotor with much force. It isn’t simply that solar and nuclear will be the preferred options for energy on Mars; they are the only options. All energy innovations associated with Mars colonisation will need to be long-lasting, and they will be intrinsically carbon-free.

Finally, and perhaps most importantly, living on the Martian surface – and especially returning home from it – will require an ability to manipulate the Martian atmosphere. On Earth, the primary gases in the air we breathe are nitrogen, oxygen, and several trace gases including carbon dioxide. On Mars, the atmosphere is extremely thin, just a little over 1 per cent of the density of Earth’s. And although oxygen and nitrogen are essentially absent, carbon dioxide is hyper-abundant, constituting 95 per cent of the Martian atmosphere.

The abundant CO2 in the Martian atmosphere will be a crucial resource for a self-sustaining Mars colony. By extracting carbon molecules, we can react them with hydrogen to produce methane, a rocket fuel that will send our astronauts home. We can also pull oxygen out of the CO2 to make water. The basic chemistry involved in these reactions has been known for centuries, but there’s been little incentive to innovate the techniques used to manipulate them. Water and oxygen are so bountiful on Earth that we’ve never had much incentive to develop efficient ways of extracting them from carbon dioxide. But today it is becoming clear that processing CO2 could be the key to reducing carbon emissions and creating useful materials such as plastics without fossil fuels.

The challenge of colonising Mars shares remarkable DNA with the challenges we face here on Earth. Living on Mars will require mastery of recycling matter and water, producing food from barren and arid soil, generating carbon-free nuclear and solar energy, building advanced batteries and materials, and extracting and storing carbon from atmospheric carbon dioxide – and doing it all at once. The dreamers, thinkers and explorers who decide to go to Mars will, by necessity, fuel unprecedented lateral innovations.

Lateral innovations between Earth and space aren’t merely speculation. They are happening right now. In the 1970s, the first Landsat mission began returning images of the whole Earth every 16 days. Over the ensuing 45 years, new Landsat sensors have consistently provided that coverage. With each iteration (Landsat 8 is flying today), improved detectors have brought more and more of the spectrum into view. The resulting data have transformed scientific awareness of our planet’s large-scale ecology and environment. And yet, many fundamental aspects have remained the same over those decades. Landsat captures most of the features of the Earth’s surface at 30-metre spatial resolution. At this scale, agricultural fields and large patches of forests are clearly seen, but individual homes and trees are not.

Recently, two private companies have reimagined Earth imaging. Skybox (acquired by Google in 2014) and Planet Labs (which I now call home) have begun to manufacture satellites that are smaller and far less costly than either the Landsat system or most other commercial remote-sensing platforms. Both are developing new approaches and new services – Skybox by producing high-resolution video from space, and Planet Labs by imaging the entire Earth every day.

Lateral innovation is the driving force behind these advances. Pete Klupar, who was director of engineering at NASA’s Ames Research Center from 2006 to 2011, has spoken admiringly about the ways the two companies draw on technology from unconventional sources: ‘They are using IMUs [inertial measurement units] from video games, radio components from cellphones, processors meant for automobiles and medical devices, reaction wheels meant for dental tools, cameras intended for professional photography and the movies, and open-source software available on the internet.’

The next time you have a cavity drilled, you might want to distract yourself by thinking about orbital mechanics. The drill that your dentist is holding is one of the lateral innovations employed by engineers at Planet Labs. They are relying on a modern version of an old hands-on museum trick in which a docent will seat a guest in a bar stool, place a bike wheel in their hands, and then spin it up. The docent then asks the guest to rotate the bike wheel perpendicularly, and viola! The bar stool starts turning. The effect is caused by conservation of angular momentum. The spinning wheel has a vector of force pushing out of it, and when you try to push that vector it has to have somewhere to go. That is a reaction wheel.

Early satellites had bits of measuring tape sticking out as radio antennas. Necessity is the mother of lateral innovation

Satellites have for many decades used reaction wheels to point with exquisite accuracy along three axes. The effect works in both zero and Earth-normal gravity, and does not require any propellant. With three reaction wheels (four for redundancy), satellites can stare dead-on target. The planet-hunting Kepler space telescope failed its primary mission after two of its four reaction wheels stopped turning; its reaction wheels, like those on most satellites, were a custom job. For the hundreds of low-cost, tiny satellites to be launched by Planet Labs and a number of other ‘small-sat’ companies, custom fabrication was not an option. It also was not a necessity, the engineers realised. All they needed was a fast-spinning rotor.

As the medical-devices industry refined components to create a beautiful drill – one that pulls two orders of magnitude faster than a Ferrari – it’s safe to say they never imagined the hardware would make its way to space. The decision made by Planet Labs engineers was one of necessity: the only way to build the satellites quickly and cheaply enough was to use off-the-shelf components that could be plugged into a satellite with little modification. Early satellites had bits of measuring tape (the regular hardware-store one with yellow tongues) sticking out to function as radio antennas. Low cost, good performance and high reliability were essential to convince investors that Planet Labs could succeed. Necessity was the mother of lateral innovation.

Since its first demonstration launch in 2013, Planet Labs has successfully deployed 133 satellites. In late 2014, the company lost a flock of 26 satellites when an Antares rocket exploded a few seconds off the launch pad. The Planet Labs team rebounded almost immediately, assembling and shipping out two new satellites in just nine days. We could never have done that without lateral innovation, without pulling drill motors and solid-state drives and CPUs from the shelf.

The lateral flow goes both ways. Just as Planet Labs pulled off-the-shelf innovations into its satellite hardware, innovations developed for spaceflight are benefiting other industries. In 2013, SpaceX hosted 3D metal-printing firms at their warehouse in Hawthorne, California to demonstrate how they ‘print’ rocket engines for the human-rated version of the Dragon space capsule. Previous human-rated capsules used an escape tower that sits on top of the capsule like a needle. It has to be jettisoned during launch if it isn’t used. By contrast, SpaceX built the engines right into the side of the capsule. If the engines aren’t used in a rescue operation during launch, then they can be fired later to land the capsule. SpaceX specifically built them to ensure that the Dragon capsule is capable of landing on Mars.

The design of these SuperDraco engines is complex, but not more complex than, say, a device that could suck CO2 out of the hot gases in a coal-fire smokestack. The technology to capture and contain carbon emissions has eluded sustainability engineers for a quarter century. It’s just too costly, according to those who have looked into it. Maybe it’s worth taking a stab at innovating it laterally rather than directly. Three-dimensional metal printing of the type used by SpaceX probably provides about the right level of precision. A carbon-capture-and-sequestration instrument is about as complex as a rocket engine. In essence, they do the same thing, just in reverse: a rocket engine supervises a chemical reaction in the additive sense, and a carbon-capture device carries out a chemical subtraction.

The innovations covered here are not spinoffs in the sense that NASA and other government agencies often tout. (Not incidentally, ‘Spinoffs’ is the name of a report NASA periodically sends to Congress to justify spending on space systems.) We’re not talking about commercialising astronaut drinks into Tang. We’re talking about full-fledged, self-sustaining pipelines of innovation that come laterally to space hardware (turning dental drills into reaction wheels) or from space hardware (3D metal printing, now finding its way into many types of industrial manufacturing). Either way, the innovations were motivated by mission-driven problem-solving. Dental drill reaction wheels exist only because Planet Labs embarked on the enormous task of imaging the entire Earth every day. SpaceX’s enhancements in 3D metal printing were overtly driven by the company founder Elon Musk’s desire to colonise the Red Planet.

after seeing what lateral innovation can do, I no longer believe that the sensible approach is the correct one

The difference between assuaging skeptical members of Congress with a report on spinoffs and drawing in true innovators can be seen on the factory floor at SpaceX’s Hawthorne headquarters. In a report for 60 Minutes in 2012, the journalist Scott Pelley queried the former NASA astronaut Garrett Reisman about his decision to join SpaceX: ‘You have so much background in engineering, such a long and enviable career at NASA. You could have easily gotten a job at Boeing or at Lockheed, but you came here and I wonder why.’ Reisman replied: ‘If you had a chance to go back in time and work with Howard Hughes when he was creating TWA, if you had a chance to be there at that moment when it was the dawn of a brand new era[…] wouldn’t you want to do that? I mean, that’s why I’m here.’

Engineers such as Reisman are working hard to take us to Mars. Indeed, SpaceX recently topped a list of tech companies rated based on how much the employees thought their work ‘makes the world a better place’. Musk’s vision extends even beyond colonising Mars. In the very long run, he envisions ‘terraforming’ the planet – engineering its climate to be more Earthlike so that it could support life in the open air.

From a conservative, rational perspective, it would be easy to impugn the high-frontier aspects of SpaceX’s mission as a waste of talent, time, and technology. Given the urgency of protecting human welfare on the only planet we presently inhabit, it might seem sensible to keep our eyes fixed on the problems immediately ahead of us. But after seeing what lateral innovation can do, I no longer believe that the sensible approach is the correct one. We have to look past the foreground; we have to look beyond our planet. We have to go to Mars.